General

Hydropuls® is a pulse method for increasing the performance of production wells and production boreholes as well as groundwater measuring points.

The pulse generator produces sequences of pressure pulses. The valve system of the pulse generator is capable of releasing the energy accumulated in the generator in the form of high-pressure gas in very short switching times (milliseconds), thereby creating hydraulic shock waves.

At the same time, the sudden change in volume causes a cavitation effect (cavitation), which leads to the formation of a “vacuum bubble” that subsequently collapses, generating a hydraulic “suction wave.”

This method is an approved method according to DVGW Merkblatt W 130.

Principle

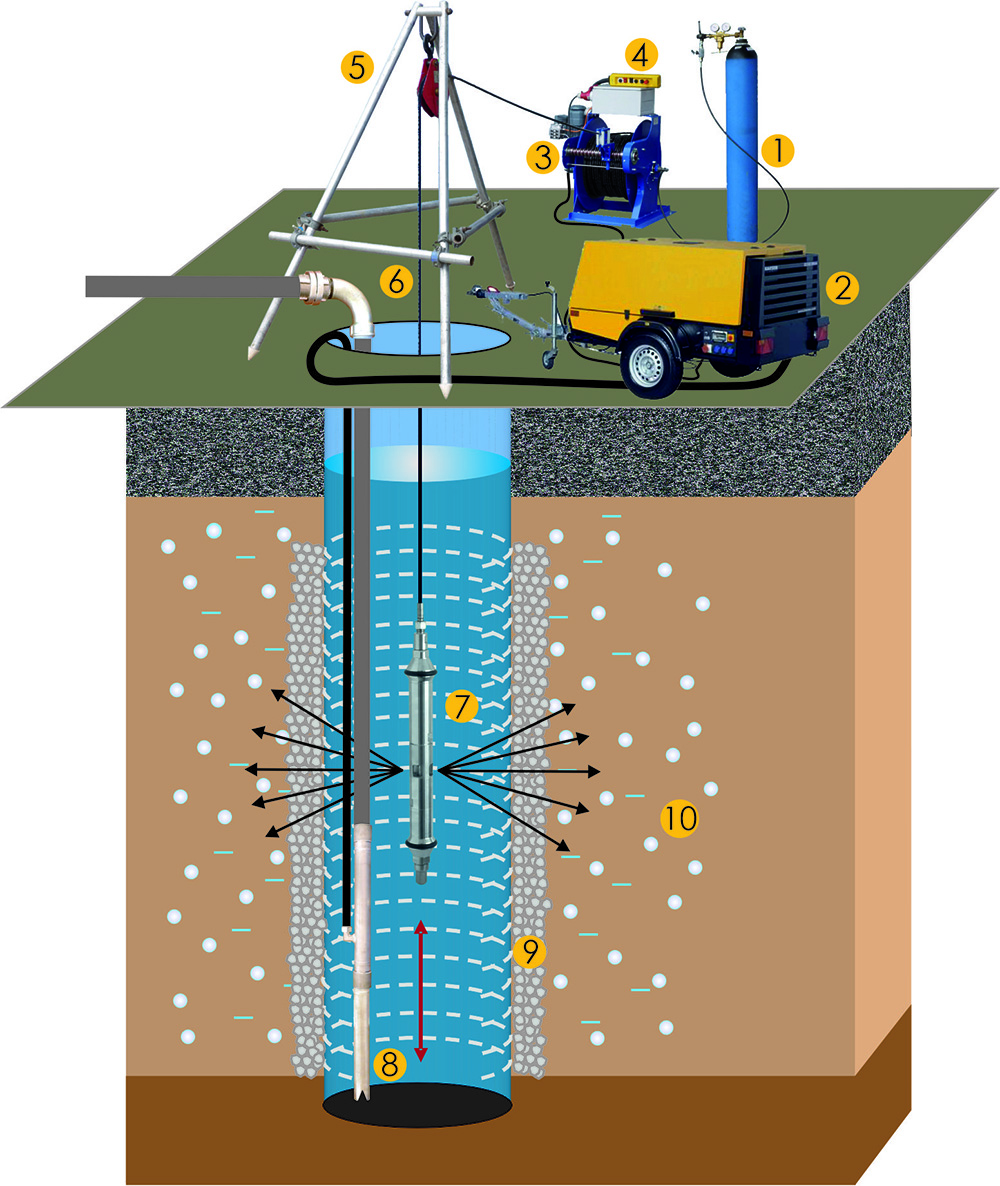

Schematic sketch – Procedure sequence:

- Gas cylinder (nitrogen / air)

- Media supply – compressed air/electrical energy

- Electric hose winch with depth indicator

- Control unit

- Tripod with return pulley

- Compressed air hose

- Pulse generator

- Underground pump/ airlift

- Filter pipe with gravel layer

- Aquifer

Parameters

Features and technical specifications of the process